Why is Green Hydrogen so Hard to Transport?

The Situation:

Green hydrogen has garnered significant attention as a promising sustainable energy solution, evident from the new U.S. clean hydrogen strategy and road map and discussions about investing in green hydrogen stocks. However, there are a variety of challenges associated with green hydrogen which have the potential to hinder its adoption. One of the main challenges associated with green hydrogen is hydrogen transportation. Safety, infrastructure, and cost pose a wide and interconnected network of challenges. In this blog, we delve into these issues, shedding light on technological advancements that enable feasible hydrogen transportation.

Safety Issues:

Transporting green hydrogen, whether in its liquid or gaseous form, poses numerous challenges. Hydrogen is a highly flammable substance and has the ability to ignite at concentrations as low as 4% in the air. Additionally, its wide flammability range makes transportation potentially hazardous not only for the transporters but also for those in proximity. Liquid hydrogen, too, is flammable and can ignite or explode upon contact with air at certain concentrations. The safety considerations that need to be accounted for are crucial when it comes to hydrogen transportation, resulting in higher complexity and cost.

Another significant safety issue in green hydrogen transportation is embrittlement. Hydrogen embrittlement occurs when H₂ atoms diffuse into the metal lattice, weakening the atomic bonds of materials. This compromises the integrity of engineering components and renders the metal more susceptible to fractures, particularly affecting high-strength steel, aluminum alloys, and titanium alloys. These fractures may lead to sudden failure and pose risks to property and human safety.

Infrastructure Issues:

The transportation of green hydrogen faces some key infrastructure challenges due to its unique properties. When transported via truck or ship, green hydrogen is typically in a compressed or liquefied form in order to reduce volume and make transportation easier. However, these processes are expensive and require complex and highly specialized facilities in order to prepare the green energy source for transport.

An alternative transportation method involves pipelines, but this option comes with its own set of challenges. Existing natural gas pipelines would need modifications to accommodate green hydrogen due to its small molecular size. The potential for the tiny hydrogen molecules to permeate the ground or cause embrittlement in metals necessitates a dedicated network of hydrogen pipelines constructed from suitable materials, resulting in a substantial and costly undertaking.

Moreover, the recent surge in the popularity of green hydrogen as an energy source raises new challenges concerning scale-up. While small-scale green hydrogen production can be relatively efficient, meeting the growing demand at a larger scale requires a significant expansion of infrastructure.

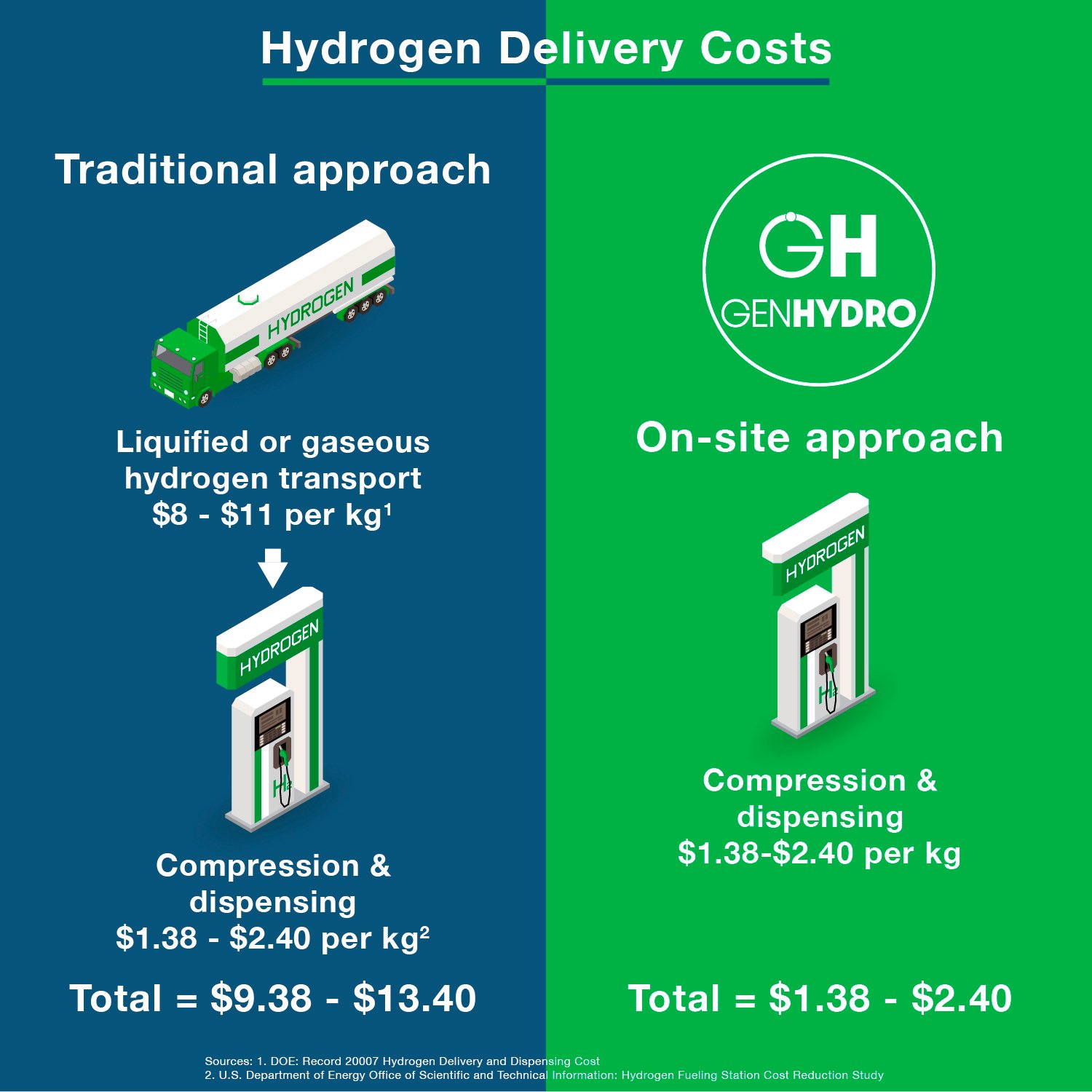

Cost Issues:

Green hydrogen transportation is an expensive undertaking. The safety measures and infrastructure required is costly, but that's not all that makes green hydrogen transportation so pricy. Hydrogens' low energy density, bespoke transport vessels, and regulatory compliance all add to hydrogen transportation's high price point.

One of the key issues associated with the transportation of green hydrogen relates to its low energy density. Energy density refers to the amount of energy stored in a given volume or mass of a substance. Hydrogen has a very low energy density by volume, meaning that a large volume of hydrogen contains relatively little energy compared to other fuels like gasoline or diesel. Karmakar provides the numbers comparing hydrogen to gasoline.

On a weight basis, hydrogen has nearly three times the energy content of gasoline (120 megajoules per kilogram [MJ/kg] versus 44 MJ/kg), but on a volume basis, the situation is reversed (3 megajoules per liter [MJ/L] at 5000 pounds per square inch [psi] or 8 MJ/L as a liquid versus 32 MJ/L for gasoline).

When hydrogen is compressed or liquefied, there can be energy losses during those processes. These losses translate into additional costs.

Green hydrogen is commonly transported using various means such as trucks, pipelines, or rail. Each of these transportation methods requires specialized vessels designed to handle the compressed gas or liquid hydrogen safely. The cryogenic tankers, pipelines, and tube trailers that are used must meet strict safety standards to prevent leaks or accidents, considering hydrogen's volatile and flammable nature. As a result, acquiring and maintaining these vessels is not only costly but also necessitates regular safety checks and measures to ensure safe transportation which may incur additional costs.

The GenHydro Solution:

GenHydro is here to help navigate the tangled web of issues associated with green hydrogen. With our revolutionary new "micro power plant" technology, the GenHydro reactor produces hydrogen fuel without releasing any carbon emissions. GenHydro chemist and engineer, Avishek Karmakar, elaborates on the technology and challenges with hydrogen transportation.

GenHydro offers a unique solution to the existing problems related to hydrogen transport. We use Aluminum – one of the three most abundant elements on earth to produce Hydrogen via a “chemical reaction” which in turn results in decentralization and increases the resilience of hydrogen production while addressing the existing challenges of Hydrogen transportation.

By shipping the scrap metal fuel to produce the hydrogen where it's needed, GenHydro overcomes all the issues associated with hydrogen transportation. It doesn't require intense safety precautions, new infrastructure, or a million-dollar investment. GenHydro's reactor system makes green hydrogen transportation feasible, economical, and scalable today. Karmakar states, "GenHydro’s technology could significantly lower the price of Hydrogen production and help achieve the target of Hydrogen Energy EarthShot which seeks to reduce the cost of clean hydrogen to $1 per 1 kilogram in one decade".

To learn more about GenHydro's tech, check out our white paper or sign up for our newsletter below.